Tungsten carbide is a material of high hardness and wear resistance. Lifetime of carbide tools can be few times longer compared to their steel equivalents. Tungsten carbide is made from powders that are first pre-formed to desired shape, next sintered and presses under high pressure. In the sintering process tolerances of 0.2-0.4 mm and surface roughness of about Ra 1.6 can be reached. Lastly the part is machined to it’s final shape.

Applications

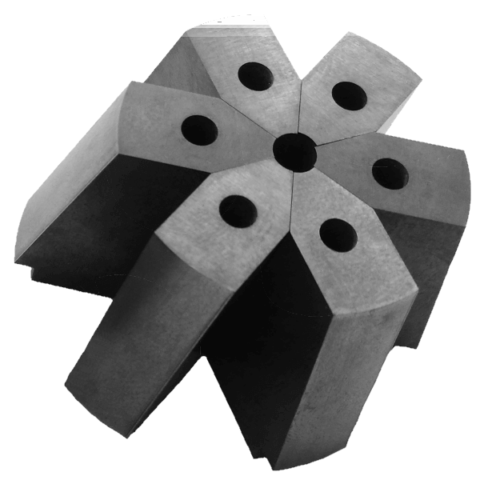

Tungsten carbide found application in many branches of industry to manufacture machine parts such as:

- trimming dies and punches,

- forming dies and punches, calibrators,

- forging dies and punches,

- forming and guiding rollers,

- bushes,

- wire and thread guides,

- nozzles for powders and grinding media,

- blanks and semi-finished sintered products.

These parts are often made as tungsten carbide insert fitted into aluminum or steel casing.

Machining

Tungsten carbide, because of it’s high hardness and brittleness usually is machined by:

- grinding,

- polishing,

- EDM processing.

Thanks to that it is possible to achieve tight tolerances (even below 0.01 mm) and excellent ‘mirror polished’ surface roughness (below Ra 0.1), even with complex shapes.

We provide both finished products as well as sintered blanks -emi-products for further processing.