Fiber lasers have a much more energy efficient than Co2 lasers. They offer long service life with minimal maintenance required. They are meant for work with metals and some plastics, but are also able to handle other materials like tungsten carbide, technical ceramics, wood, leather or rubber. However, because of the wavelength of the laser they are unable to work with transparent materials.

Marking with fiber lasers can be achieved by engraving or annealing. Tthanks to thhis it is possible to permanently mark even polished surfaces without damaging them. Lasers can be also used for cutting thin materials, but this is not their main purpose and should not be performed regularily.

Standard equpiment:

-main unit

-foot switch

-protective glasses

-software

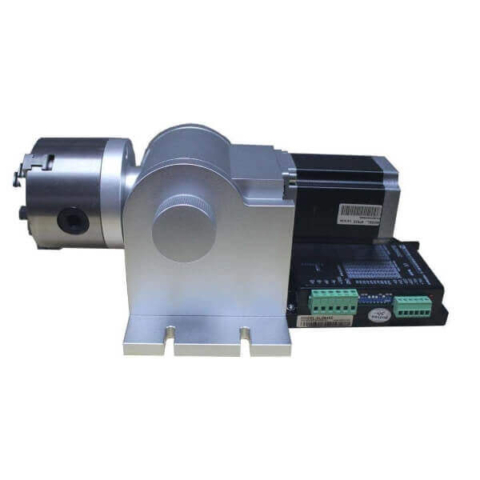

Optional equipment:

-rotary device for marking along the circumference

-computer

-work table

| Laser type | Fiber | ||

| Laser power | 20 W | 30 W | 50 W |

| Wavelength | 1064 nm | ||

| Beam diameter | 7±1 mm | ||

| Frequency | 20-80 kHz | 50-100 kHz | |

| Marking depth | 0.01-0.3 mm | 0.01-0.4 mm | 0.01-0.5 mm |

| Work area | 70×70 mm/110×110 mm/175×175 mm | ||

| Power consumption | 500 W | 800 W | 1200 W |

| Voltage | 230V/50Hz/ 15A | ||

| Cooling | Air | ||